Abstract

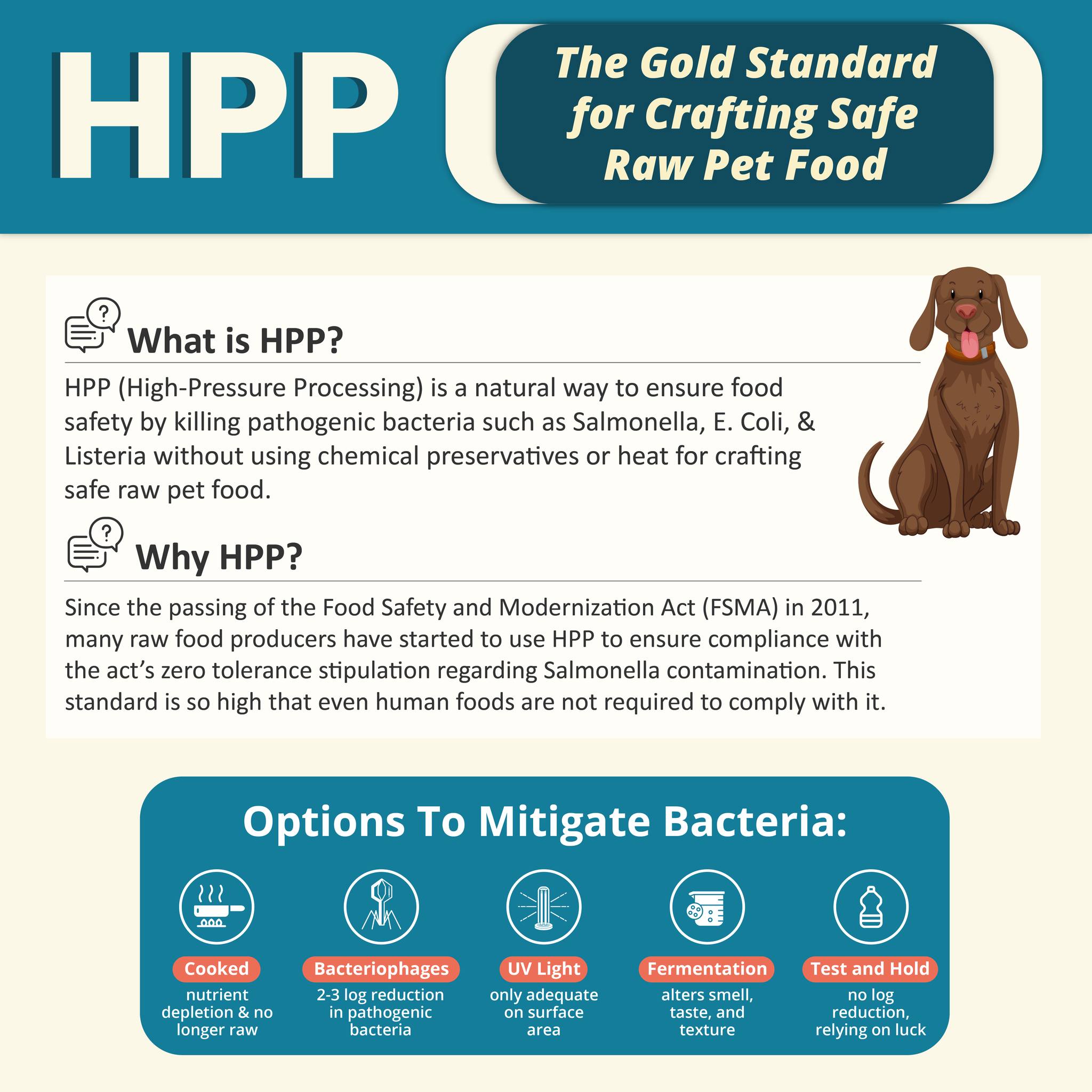

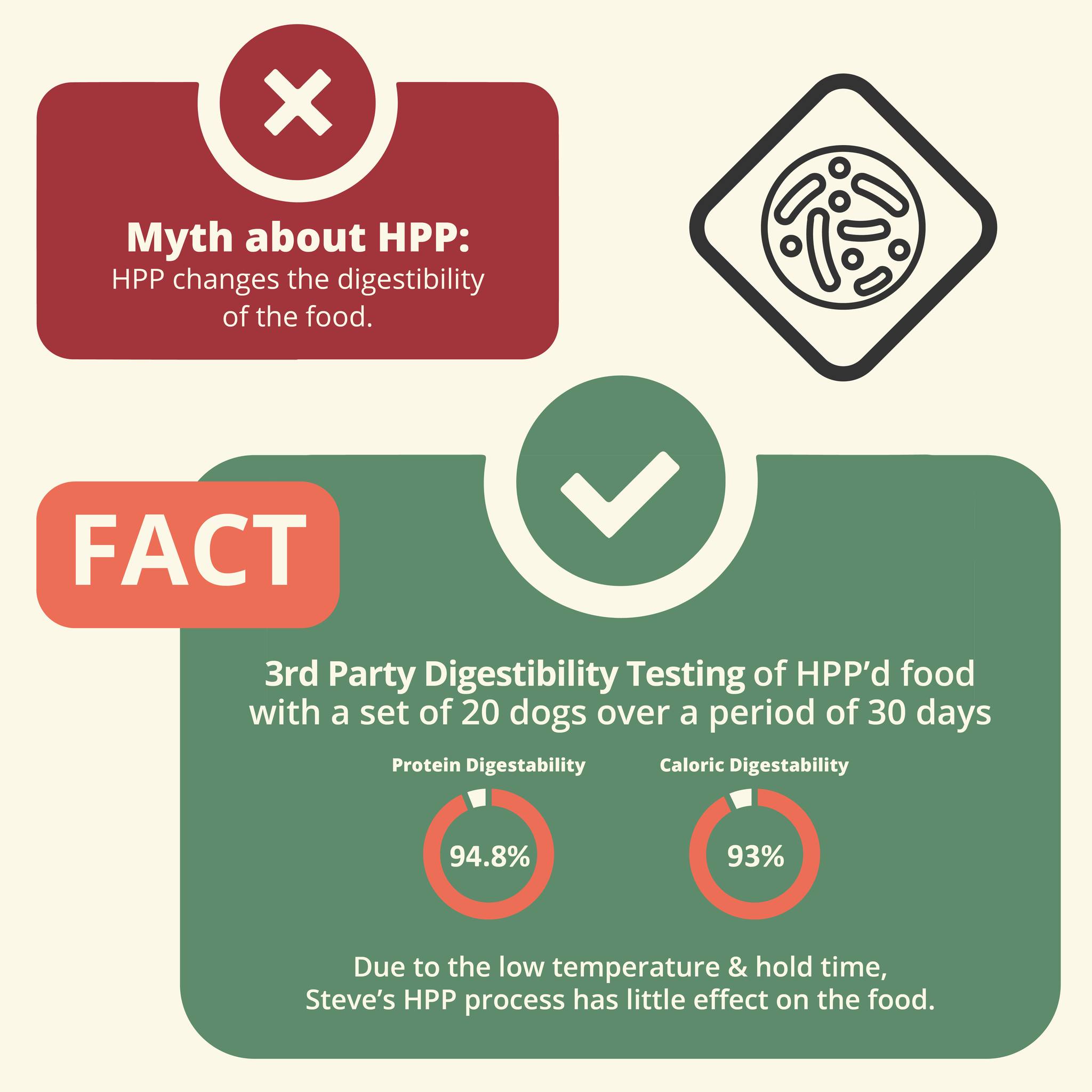

The need for minimally processed, microbiologically safe, chemical-free raw pet food is growing in demand exponentially. For several years the use of high-pressure process has shown to be a viable solution in the human food category and is embraced by manufacturers looking to manage the microbial environment without synthetic preservatives. However, before employing it in the SRF raw food diets it is of vital importance to understand the kinetics of HPP on nutritional validity, toxicity, and taste. For two years, Steve’s Real Food has conducted both internal research and sought out outside sources to fully understand the best practices within this process and its effect on the food.

We conducted internal testing of 95 nutrients and saw an insignificant change in nutrient value. This combined with extensive research done by 3rd parties has lead us to the conclusion that HPPed raw diets and non-HPP raw diets are bioequivalent. We also tested for the migration of toxins from plastic packaging and found no change in BHA. Finally, the additional testing on enzymatic and probiotic activity has deemed this process as a viable option to manage the microbial environment and preserve all our raw meat diets.

Tests Conducted

We conducted several tests on HPP raw meat diets and non-HPP raw meat diets to determine the effects of the process on proteins, fats, vitamins, minerals, enzymes, probiotics and toxins. The tests were conducted on the same lot numbers to ensure that the biological makeup of the control group and the test group were equivalent.

The objective of the tests was to first determine the effects of high-pressure process on raw meat diets, and second to identify any negative side effects that the process may produce.

We divided our testing into four different sections; nutritional, enzymatic, probiotic, and toxins.

Nutritional Tests Conducted

Prior to implementing the HPP process on our poultry, we ran two full nutritional analysis panels on chicken using the same lot for both the control group and the HPP treated group. This test consisted of 95 vitamins, minerals, proteins, fats, and fiber. It was shown that there was minimal effect on all of these nutrients with the exception of 4 vitamins which had moderate losses. These losses were not significant enough to fall below the AAFCO’s recommended amount*. We continued to do regular testing going forward to achieve more data points, specifically on the ones where we found a moderate nutritional change.

Below are the percent changes for all of the AAFCO nutrients.

| Sample: Raw Chicken Diet | Amount Changed | |

| Nutrient | ||

| Moisture | 1.0 | % |

| Crude Protein | -0.7 | % |

| Arginine | 0 | % |

| Histidine | 0.02 | % |

| Isoleucine | 0.02 | % |

| Leucine | 0.02 | % |

| Lysine | 0.01 | % |

| Methionine | 0.02 | % |

| Methionine-cystine | 0.03 | % |

| Phenylalanine | 0.01 | % |

| Phenylalanine-tyrosine | 0.01 | % |

| Threonine | 0.00 | % |

| Tryptophan | 0.02 | % |

| Valine | 0.03 | % |

| Crude Fat | 0.74 | % |

| Crude Fiber | 0.07 | % |

| Linoleic Acid | 0.17 | % |

| alpha-Linolenic acid | 0.01 | % |

| Eicosapentaenoic+docosahexaenoic acid | 0.00 | % |

| Omega 3 | 0.02 | % |

| Omega 6 | 0.22 | % |

| 0.00 | % | |

| Minerals | ||

| Ash | 0.09 | % |

| Calcium | 0.13 | % |

| Phosphorus | 0.07 | % |

| Potassium | 0.01 | % |

| Sodium | 0.01 | % |

| Chloride | 0.00 | % |

| Magnesium | 0.00 | % |

| Iron | 0.90 | mg/kg |

| Copper | -0.20 | mg/kg |

| Manganese | 0.01 | mg/kg |

| Zinc | 1.10 | mg/kg |

| Iodine | 0.00 | mg/kg |

| Selenium | 0.00 | mg/kg |

| Vitamins | ||

| Vitamin A (Retinol) | -176 | IU/kg |

| VitaminD | 0 | IU/kg |

| Vitamin E | 0 | IU/kg |

| Vitamine K | 0 | IU/kg |

| Thiamine | 0.91 | mg/kg |

| Riboflavin | 0.11 | mg/kg |

| Pantothenic acid | -3.2 | mg/kg |

| Niacin | 3.3 | mg/kg |

| Pyridoxine | -0.07 | mg/kg |

| Folic acid | 0 | mg/kg |

| Vitamin B12 | -0.216 | mg/kg |

| Choline | 0 | mg/kg |

| Taurine | 0 | mg/kg |

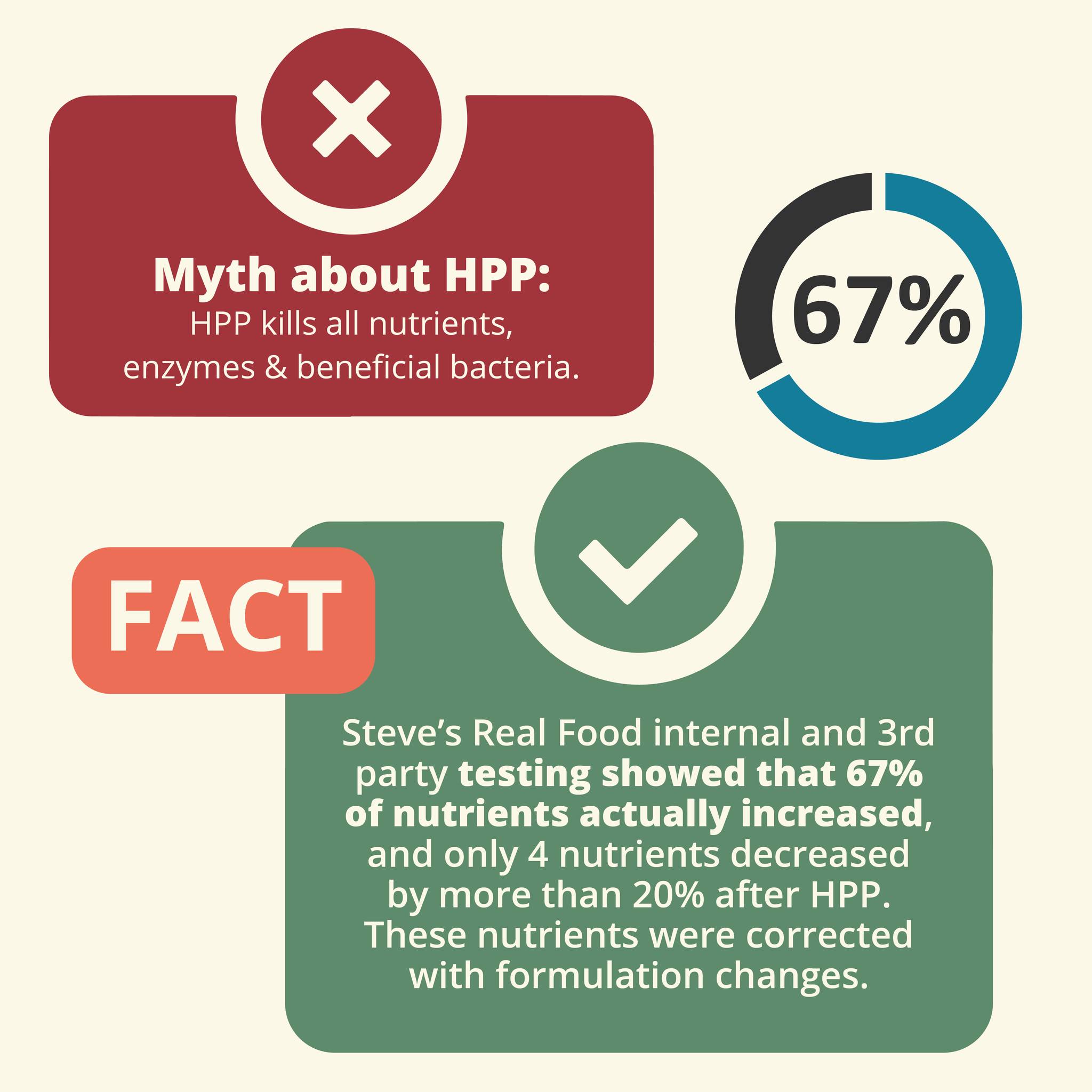

As shown, 67% of the nutrients had an increase in value while only 17% had decreases. There are only four nutrients with losses greater than 20% which did flag concern. However, after further research, we found that these nutrients were in such abundance that we were still far above AAFCO guidelines.

Below is a breakdown of the nutrients with losses greater than 20%.

| Vitamin | AAFCO Minimum | Average Amount (dry matter) |

| Vitamin A (Retinol) | 5000 IU/kg | 5538 IU/kg |

| Pantothenic acid | 12 mg/kg | 13.1 mg/kg |

| Pyridoxine | 1.5 mg/kg | 1.7 mg/kg |

| Vitamin B12 | 0.028 mg/kg | 0.169 mg/kg |

*We have updated the formulas as follows to ensure that in the HPP formula these vitamins are met in abundance above the AAFCO minimums.

- Increased Liver for more Vitamin A

- Increased Organ Meat overall for more Pantothenic Acid and Vitamin B12

- Increased the Muscle Meat for more Pyridoxine and Vitamin B12

It is noted that the calcium and phosphorus levels increase. This increase is not of concern due to the CA:PH ratio maintained within the optimal level of 1-2:1. However, due to the need to increase the meat and organ levels, we have reduced the raw bone which in turn maintains our calcium and phosphorus levels.

Nutritional Tests Summary: There were minimal reductions in minerals and slight reductions in four vitamins of which we have made formula adjustments to account for the changes.

Enzymes Tests Conducted

Enzymes are critical in our raw food diet and are one of the main elements that make a raw diet more nutritious than a lightly cooked diet. It is of critical importance that we understand the effect of high-pressure pasteurization on enzymatic activity. To achieve this goal we conducted both internal tests on our raw diets and researched 3rd party studies that contained extensive testing on food-derived enzymes.

Our internal testing was done on the raw chicken diet. We tested the enzymatic activity on the same lot of food prior to HPP and post HPP. The results were definitive that the HPP process had an insignificant effect on enzymatic activity. This was then supported by the third-party research we found.

In a study by “Pressure-Induced Inactivation of Selected Food Enzyme” published in the Journal of Food Science it was found that enzymatic activity has little degradation after the HPP process using a pressure of 600 MPa. The study was conducted to find out at what pressures the enzymes would have to be put under to become fully inactivated. Most enzymes required an MPa of 800 or more for long periods of time. They tested many pressures, temperatures, and immersion mediums to fully understand the effect of HPP on enzymatic activity.

They found that at ultra-high pressures such as 900MPa, there was a quick degradation in enzymatic activity reaching 100% by 5 minutes. However, by reducing the pressure and temperature, the enzymes become more stable.

One of the tests was done on the enzyme pectinesterase. A pressure of 600MPa was applied for 2 minutes at 45 Celsius and it resulted in a reduction in the activity of only 10%.

They also tested enzymatic activity in bovine milk and found that it had a protective effect. Under the same parameters stated above, the enzymatic activity had no change when tested in milk. This could be an indicator as to why our internal test showed no change in enzymatic activity.

The pressure and time that is used with our High-Pressure Technology (600MPa @ 160 sec.) are similar to what was used in this study. We do the process at a much lower temperature but it was found that under 45 Celsius, the temperature did not have an effect on enzymatic activity. Due to the similar parameters used in the study and the similar outcomes we found in our internal tests, it is determined that enzymatic activity is not affected using our High-Pressure Technology.

Enzyme Tests Summary: After doing internal testing and researching 3rd party testing we have deducted that there is no change to enzymatic activity using out HPT.

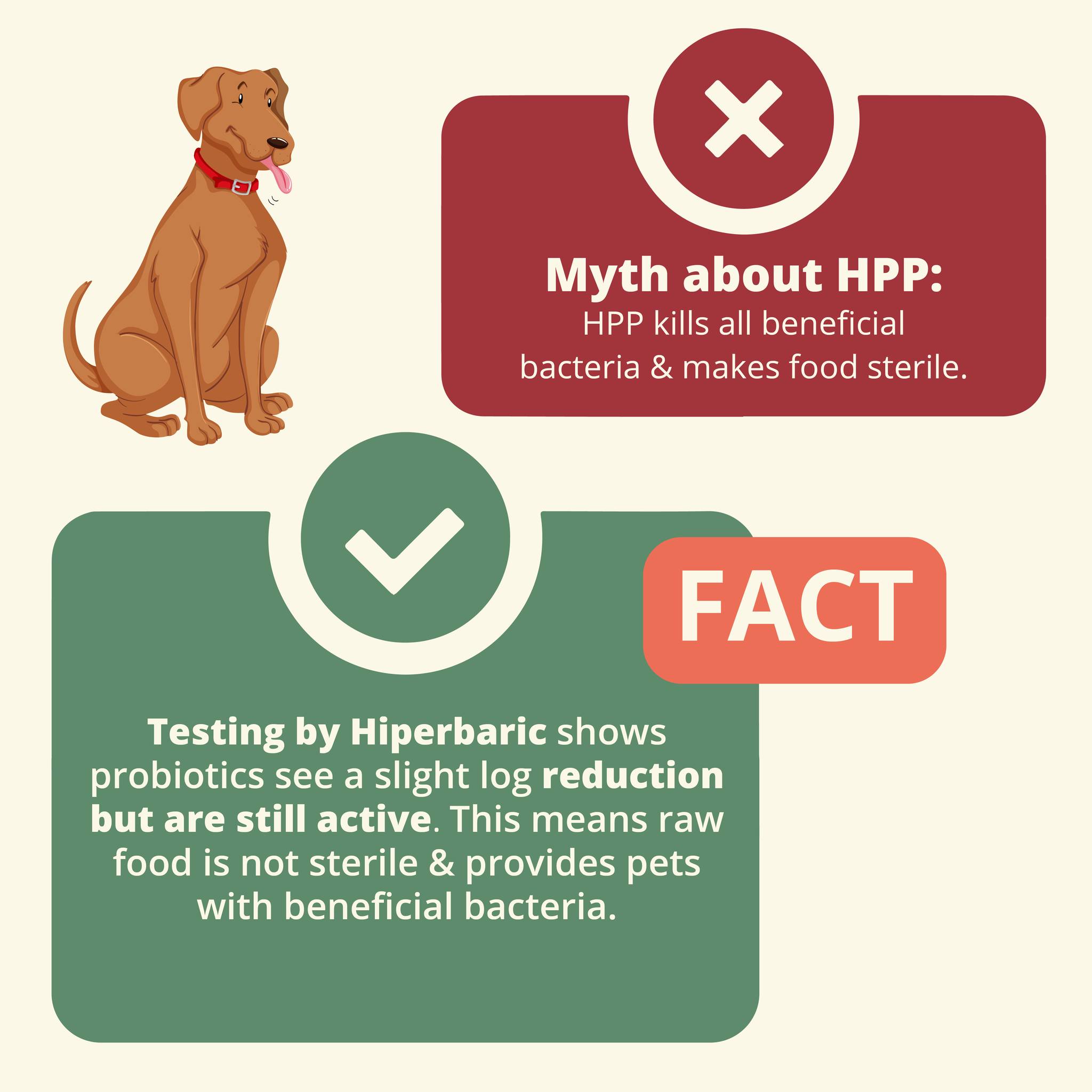

Probiotics Effects

There have been a lot of studies on how High-Pressure Pasteurization is proven to be highly effective in inactivating pathogenic bacteria and so it is important to understand its effect on healthy probiotic bacteria. There are very few studies on this but from what we found, the Lactobacillus genera of bacteria are very pressure resistant. One study cited in the article “New Insights into the High-Pressure Processing of Meat and Meat products” found that Lactobacillus only had a 2 log reduction which was regained after 6 days of chilled storage. This can be compared to Salmonella which at the same pressure had a 4 log reduction and no recovery after 60 days of chilled storage or E. Coli in raw meat that achieve total inactivation at 700MPa for 5 minutes.

Hyperbaric, the manufacture of high-pressure machinery cites a study where it was found that yogurt cultures stay active after an HPP process using 500 MPa, while mold cultures are inactivated. This study was done by a company that used it to attain patent US78549500B2.

Probiotics Effects Summary: The testing that has been done has shown little effect on the pressure-resistant “good bacteria”.

Toxins

A primary concern when pressurizing food in a plastic bag is the migration of toxins from packing to the food. The packaging that is used during the HPP process is certified BPA free, however, we wanted to be certain toxins where not being leached. We tested two batches of Turkey Diet and found that there were no detectable toxins leached from the packaging to the food. This is discussed further below.

Additional Research and Discussion

There is a lot of research on High-Pressure Processing, particularly on how it affects pathogens. In this comprehensive article, New Insights into the High‐Pressure Processing of Meat and Meat Products, there is a lot of useful information that covers the aspects of HPP and its biological effect on foods. This article provides information on both raw and cooked foods, juices, purees, and other food products. It also talks about the effect of HPP at different pressures, times, PH levels, and temperatures. Below is a summary of the information that is related to raw meat products using HPP processes similar to our pressure, time and temperature.

Effects of Texture

The HPP process can and is used to improve the tenderness of food. The pressurization process changes the structure of myofibrils, and other protein cells which make the meat more tender. The breakdown of the proteins increases cytosolic Ca2, increasing the intracellular fluid. Additionally, it is found the HPP process can increase the ph of post-rigor meats immediately after the pressure treatment.

Lipid Oxidation

Lipid oxidation leads to rancidity and off-flavors an undesirable characteristic. The high-pressure pasteurization process has shown to result in lipid oxidation if the pressure hold times are 20 minutes or more. At 600MPa, at a shorter hold time, it is shown to happen but only when the water temperatures are greater than 24 degrees Celsius (75 ℉). In a 2010 study it was found that at 600MPa for 15 minutes at 5 degrees Celsius (41 ℉), oxidation was limited significantly.

Beyond adjusting pressure and hold time, you can reduce the opportunity for lipid oxidation by eliminating the oxygen in the packaging and using vacuum-packed bags. Another practice that has shown to effectively mitigate lipid oxidation is the use of rosemary and sage extract.

Effects on Aroma

Pressure-treated beef and chicken were reported to have better aroma after 14 days of cold storage. This is attributed to the lower microbial content that would be found in pressure treated meat.

Toxic Amines

Biogenic amines (histamine, tyramine) only form in a microbial environment. High amounts of biogenic amines may have toxicological effects. The pressure pasteurization process controls the microbial environment which in turn lowers the levels of Biogenic amines.

Food that contains nitrites are most likely to result in a toxic environment after pressure treatment. Food with naturally occurring nitrites showed a decrease in the nitrite level after pressure processing.

Packaging Migration

A 2009 study showed the migration of packaging compounds into high‐pressure‐treated beef and chicken breast packed in multilayer polymeric bags. Significant migration of compounds from the plastic material was observed, but it was not enhanced by the high‐pressure treatment (400 MPa, 10 min, 12 °C). Another 2010 study showed traces of n-hexanal in HPP food, but the researchers did not state whether differences were observed between high‐pressure‐treated and untreated samples.

Bacterial Deactivation

Bacterial inactivation has been proven via the use of high-pressure pasteurization at the proper pressures, hold times, and temperatures.

- E. Coli

- In cooked ham, dry‐cured ham, and marinated beef that was inoculated at 3.5 log CFU/g, E. coli was reduced below the level of detection during 120 d of chilled storage after a high‐pressure treatment at 600 MPa for 6 min at 31 °C

- With a raw meat – 700 MPa, 20 °C for 5 min equaled Total Inactivation

- Listeria M.

- 600 MPa at 50 degrees for 5 min resulted in 3.4 log reduction of 4

- Salmonella

- 400 MPa at 17 °C for 10 min with 6 of 8 inoculated. No recovery during 60 d of chilled storage

Conclusion From Study

Information relating to the effects of high pressure on the bioequivalence of food are abundant and clear that the process does not have harmful nutritional effects. It is evident that under the proper pressure, temperature, and hold times, the effect on enzymes and probiotics are minimal. Thus, high pressure seems to be a desirable technology for the treatment of raw meat pet food products.

Study Resources

Pressure Induced Inactivation of Selected Food Enzymes – March 1996 https://onlinelibrary.wiley.com/doi/abs/10.1111/j.1365-2621.1996.tb14182.x

New Insights into the High-Pressure Processing of Meat and Meat products – April 2012

https://onlinelibrary.wiley.com/doi/full/10.1111/j.1541-4337.2012.00184.x

HPP Probiotics and Functional Products – Hiperbaric Blog – April 2017

https://blog.hiperbaric.com/en/hpp-probiotics-and-functional-products

Muscle proteinases and meat aging. 1994

https://www.ncbi.nlm.nih.gov/pubmed/22061455

Effects of high‐pressure treatment on Ca2+ release and Ca2+ uptake of sarcoplasmic – Feb 1995

https://www.ncbi.nlm.nih.gov/pubmed/7766025

Aroma development in high‐pressure‐treated beef and chicken meat compared to raw and heat treated. – Oct 2010

https://www.sciencedirect.com/science/article/abs/pii/S0309174010001695

Biogenic amines and their production by microorganisms in food – Feb 1994

https://www.sciencedirect.com/science/article/abs/pii/0924224494900701

Effects of high‐pressure processing on the volatile compounds of sliced cooked pork shoulder during refrigerated storage – Feb 2011

https://www.sciencedirect.com/science/article/pii/S0308814610008022

Beef

Beef Chicken

Chicken Whitefish

Whitefish Pork

Pork Lamb

Lamb Turkey

Turkey Turducken

Turducken All Protein

All Protein Beef

Beef Chicken

Chicken White Fish

White Fish Pork

Pork Turkey

Turkey Duck

Duck All Products

All Products Frozen Raw Pet Food

Frozen Raw Pet Food

Freeze Dried Raw Pet Food

Freeze Dried Raw Pet Food

Frozen Prey Diet

Frozen Prey Diet

Freeze Dried Protein Bites

Freeze Dried Protein Bites

Frozen Quest

Frozen Quest

Freeze Dried Quest

Freeze Dried Quest

Eggs over Easy

Eggs over Easy Steve's Merch

Steve's Merch