When we made updates to our food safety practices, we considered every part of our distribution chain—from our team and partners to our customers and their pets. It’s important to us that any changes do not result in prolonged product shortages, price increases, or a drop in the confidence you have in the quality of our food.

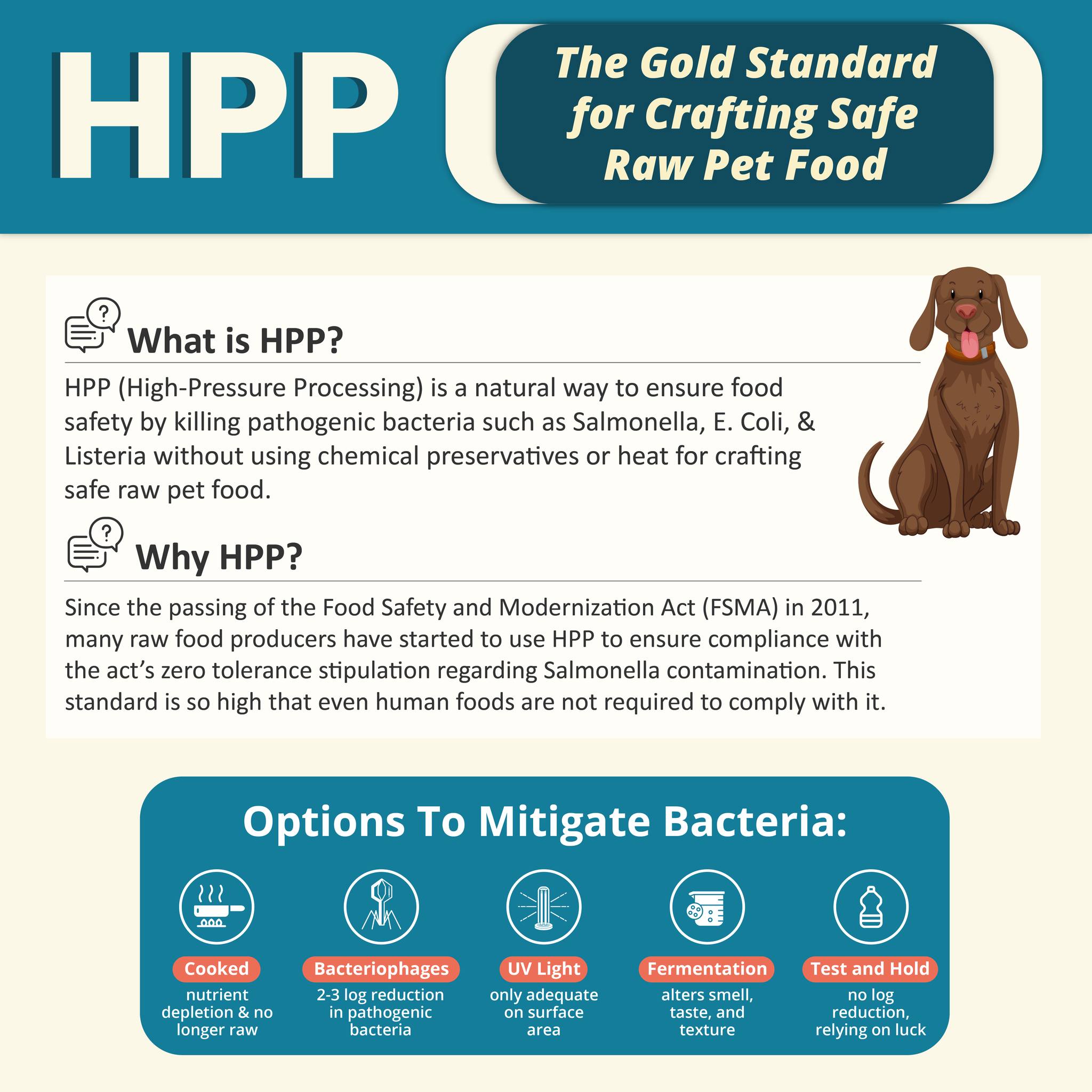

After months of evaluating various food safety options—including test-and-hold protocols, pathogen-targeted probiotic sprays, and High Pressure Processing (HPP)—we made the decision to adopt HPP processing for all our formulas.

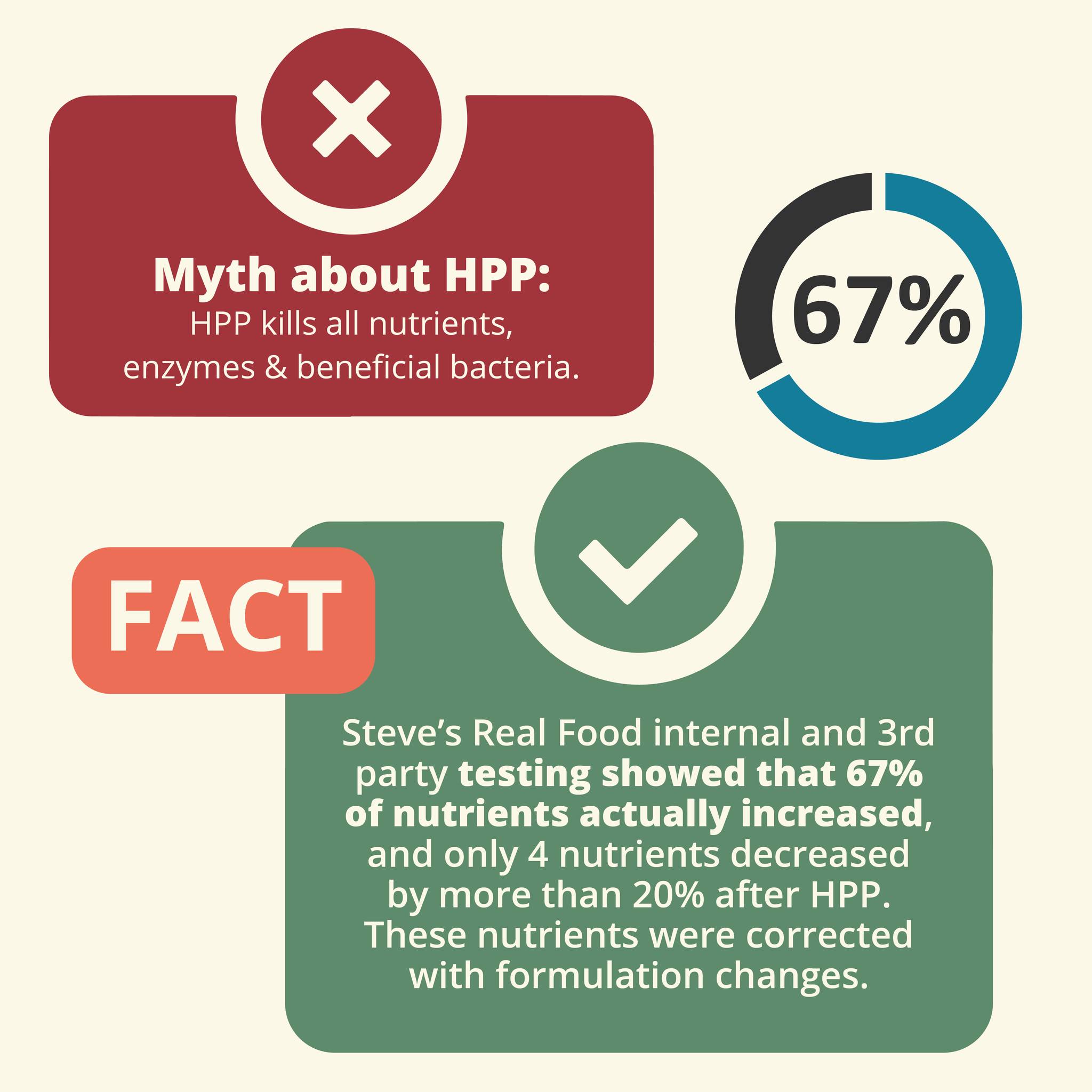

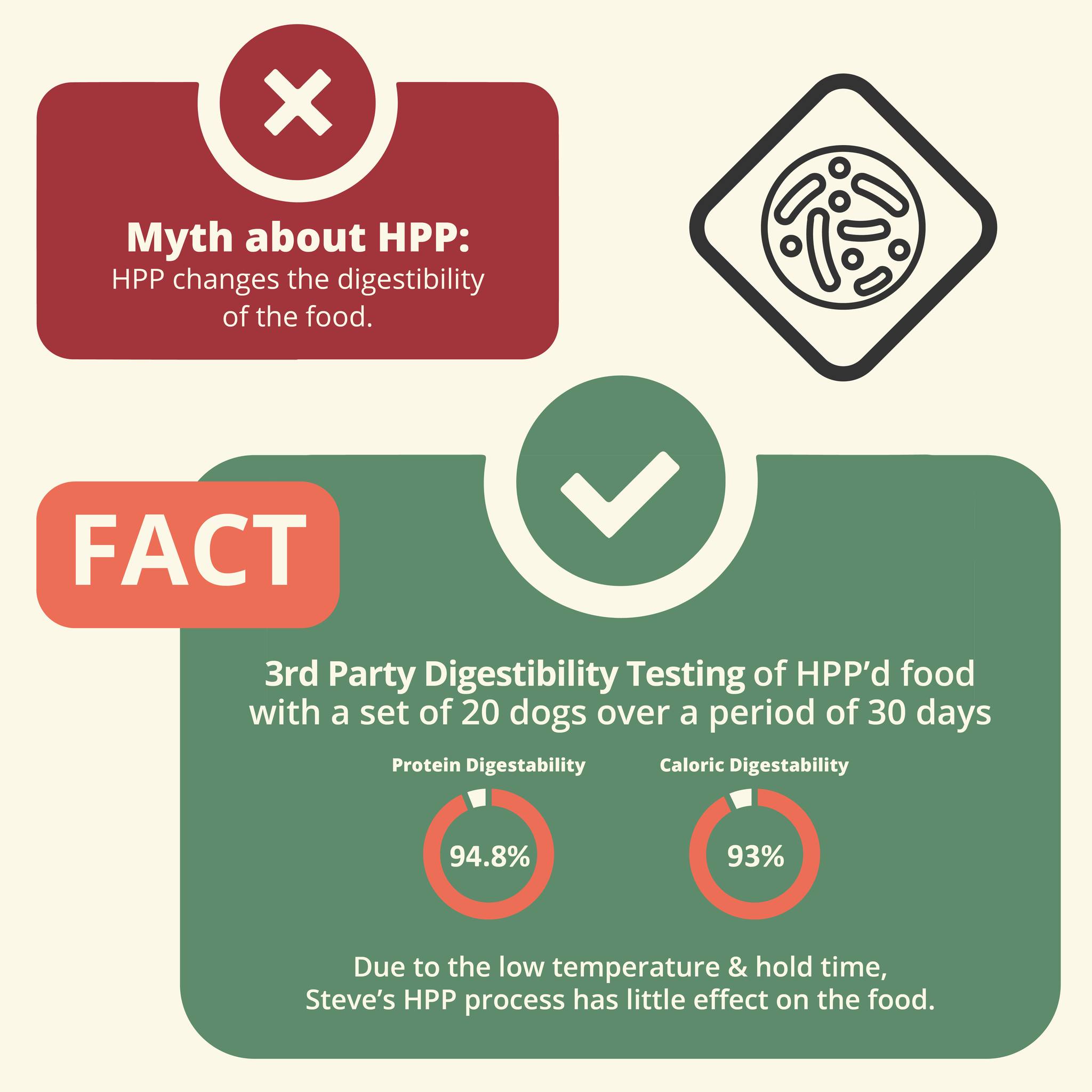

Throughout this process, we conducted extensive testing to evaluate the impact of this high pressure pasteurization process on our products’ nutritional integrity. We tested both HPP and non-HPP foods to study changes in vitamins, minerals, enzymes, probiotics, and fats. We’re happy to report that this HPP technique has a minimal effect on the nutritional value of our food.

Some highlights from our findings:

- Protein levels increased slightly, especially the amino acid tryptophan.

- Fat content remained stable.

- Calcium and phosphorus levels decreased slightly but remained above AAFCO standards, with an optimal calcium-to-phosphorus ratio maintained.

- Iron levels increased, but stayed within safe limits.

- The only notable decrease was in vitamin A. To address this, we’ve increased natural sources of vitamin A—such as liver—in our poultry-based diets.

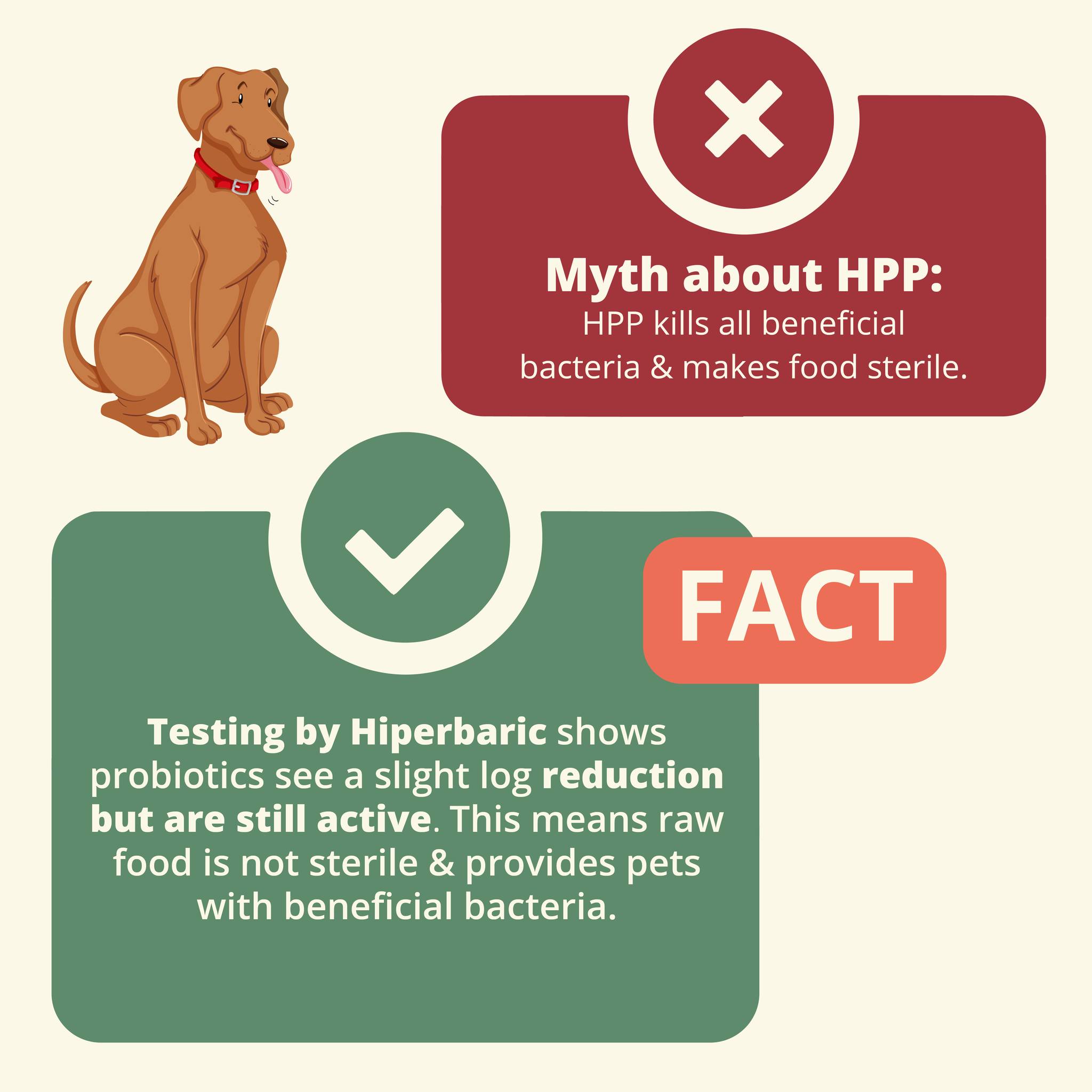

- Enzymes remained unaffected, and probiotics were minimally impacted. To boost their benefit, we now add probiotics after the HPP process.

We also increased the frequency of nutritional testing to help us closely monitor any nutritional variances and maintain our high standards.

These updates ensure we’re reducing the risk of pathogen exposure, preserving nutritional integrity, and maintaining the quality and affordability you expect from us. We’re proud to say there is no change to our pricing as a result of implementing high pressure processing.

High-Pressure Pasteurization FAQ

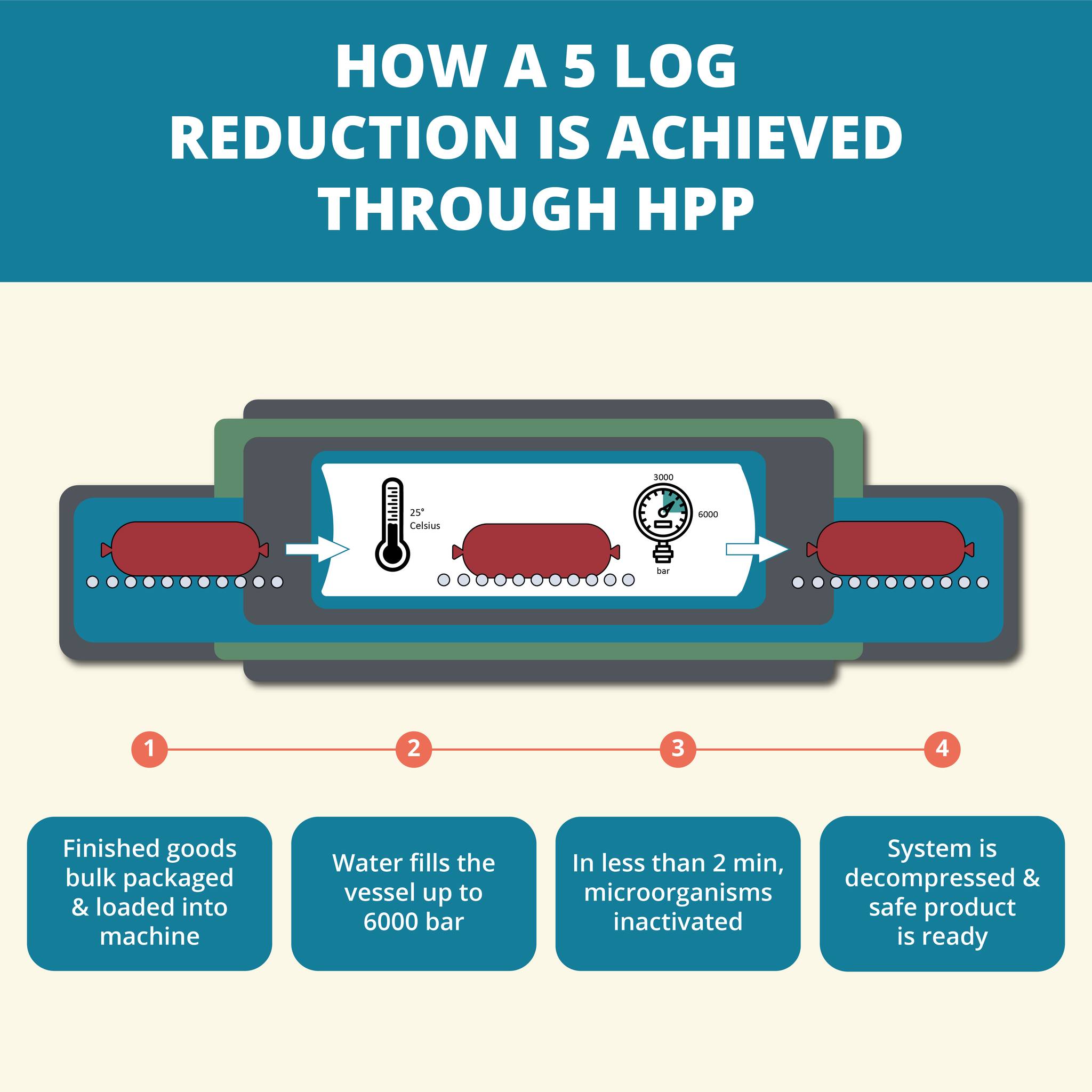

What is HPP and what is the process?

Frozen product (29 degrees) is placed in a chamber filled with chilled water (35–38 degrees). It is then pressurized for 160 seconds at 87 PSI (pounds per square inch). This pressure validates a 5-log reduction in pathogens. Water temperature in the chamber only increases by 1–2 degrees, which does not change the product temperature.

High Pressure Processing = high pressure, NOT heat.

Why did you choose to start using HPP?

As a company, we have chosen to use HPP processing on our products only after two years of researching various kill step processes that would minimize risks associated with harmful pathogens. Our focus was on keeping our pets’ diet at the highest quality possible without compromising convenience and affordability. The high pressure pasteurization process is hands down the most effective—with minimal effect on the nutritional adequacy of the food.

When did you start to do HPP?

We started distributing batches of poultry products that had gone through the HPP process in February 2019. After continued research, we decided to use high pressure processing on all frozen products in January 2020.

Does HPP change or kill natural enzymes or minerals?

After many third-party lab tests, we found that the overall protein levels of the formulas increased, specifically due to an increase in the amino acid tryptophan. Fats remained relatively the same. Calcium and phosphorus decreased but remained above AAFCO’s requirements, and the calcium-to-phosphorus ratio remained at optimal levels. Iron increased, within safe levels. The only change that we feel the need to specifically address is the observable decrease in vitamin A, which we counteract by increasing liver amounts (a great natural source of vitamin A) in the poultry diets. Surprisingly, we found no effect on enzymes and very little effect on probiotics—especially when added after the HPP technique.

What proof do you have that it did not affect enzymes?

We have conducted several third-party tests to evaluate the overall nutritional content of HPP vs. non-HPP food, and we would be happy to provide that information for you.

Does HPP make the food less palatable?

No, High Pressure Processing (HPP) does not negatively affect the palatability of raw pet food. While HPP is designed to ensure food safety by neutralizing harmful pathogens, it preserves the natural flavor and nutrition that dogs love.

Is there a color or texture change to the HPP products?

No, there is not a color change to any of our HPP products. We use the same USDA-inspected ingredients. If you notice a difference, it’s most likely due to natural variation in the meat color from batch to batch.

There is a minor change in texture due to the food being re-ground after HPP, which some dogs may notice. Occasionally, pets might pause or hesitate with their first few meals if they detect a difference—but most quickly adapt and return to their usual excitement at mealtime.

What benefits does HPP have?

The high pressure pasteurization process inactivates foodborne pathogens such as Salmonella, E. coli, and Listeria without changing the nutritional value of the food. It offers a safer option for consumers who are concerned about food safety—such as those with small children, immune-compromised individuals, or pets with immune challenges. It also eliminates the need for more severe and denaturing processes like radiation, chemical preservatives, or thermal processing.

Beef

Beef Chicken

Chicken Whitefish

Whitefish Pork

Pork Lamb

Lamb Turkey

Turkey Turducken

Turducken All Protein

All Protein Beef

Beef Chicken

Chicken White Fish

White Fish Pork

Pork Lamb

Lamb Turkey

Turkey Duck

Duck All Products

All Products Frozen Raw Pet Food

Frozen Raw Pet Food

Freeze Dried Raw Pet Food

Freeze Dried Raw Pet Food

Frozen Prey Diet

Frozen Prey Diet

Freeze Dried Protein Bites

Freeze Dried Protein Bites

Frozen Quest

Frozen Quest

Freeze Dried Quest

Freeze Dried Quest

Eggs over Easy

Eggs over Easy

Steve's Merch

Steve's Merch